If your electric motor isn’t working, there are several possible causes. A good practice is to start by confirming if the motor itself is causing the problem, as motors are often driving some other mechanism which can fail.

Lubrication Failure: Check For Grease Or Oil

Observe if a motor is permanently lubricated with grease or if it relies on a fluid such as oil, and then check to see if there is enough of that lubricant in the bearing. Most small electric motors are ‘permanently’ lubricated with grease, which sometimes burns out. Don’t use oil to lubricate a motor that was built to be greased. The oil will dry up very quickly and cause premature failure.

Remove the shaft from the bearing or vice versa and clean the shaft/bearing so you can apply fresh grease. This is a surprisingly common solution to many electric motor failures. It’s very common for grease to dry up or become overly sticky (that’s why you have to clean out the old grease).

Electric Motor Failure Due To External Causes (Jamming)

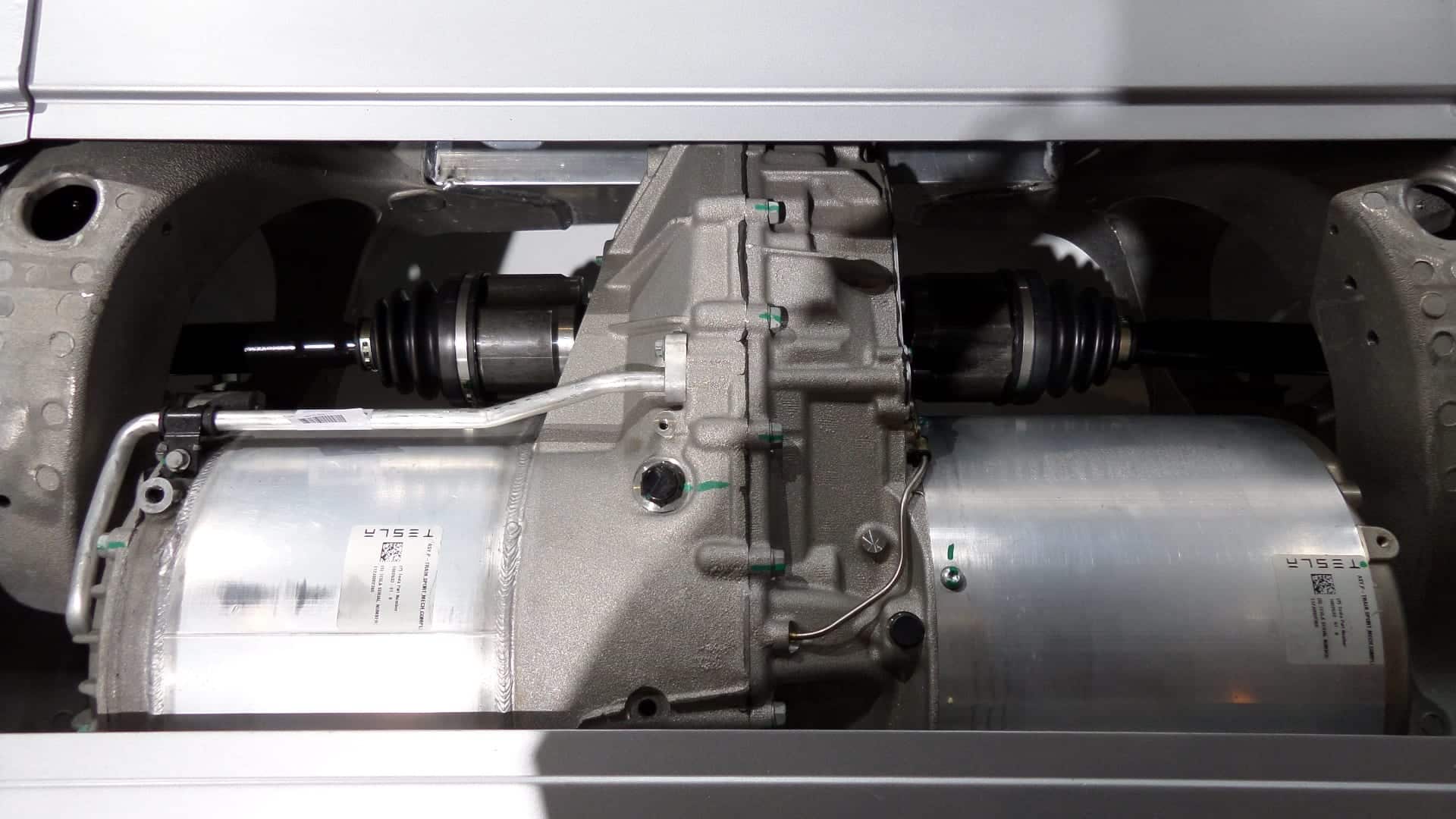

An electric motor might be driving a gearbox, pulley, or other mechanism that may be jammed or seized due to a lack of lubricant or damaged gears. Even in the case of a fan, the blade might just be jammed by a twig, leaves, ice, or even an animal (an issue that occurs with air conditioner condenser fans and central A/C blowers). To confirm if this is the problem, check if the mechanism the motor is attached to can turn freely (you may want to detach the motor, just in case the motor itself is seized).

An unfortunate consequence of such a scenario is that the motor itself won’t be able to turn, and as a result may malfunction permanently due to overheating. If a motor does not have an internal overload protector (IOL), it may draw excessive amounts of current (this is often referred to as the Locked Rotor Amperage/LRA) until the coils heat up and melt the insulation. The end result is a short circuit and the motor’s coils would have to be rewound.

This process can occur in a matter of seconds, days, or even years depending how close the motor is to its rated insulation breakdown temperature. Generally, a motor’s coils will last much longer if they are not subjected to excessive amounts of heat.

Tripped Internal Overload Protector (IOL)

A motor’s internal overload protector might shut your motor off for a certain time period so it can cool off. These protectors can be triggered by the jamming issue mentioned above (because this causes overheating), and the motor may appear to have malfunctioned. If a motor abruptly stops working and you don’t smell anything or see any smoke, wait at least 15 minutes and check to see if it will turn back on (after ensuring it is lubricated and removing the obstruction that jammed it).

Insulation Failure (Short-circuited Coils)

Over time, an electric motor’s insulation deteriorates gradually — and the crucial purpose of the insulation is to prevent the coils from coming into contact with each other (which shorts them out). If the insulation fails completely, the motor’s coils will have to be replaced (a process known as rewinding motors).

You can test insulation by checking the motor coils’ resistance with a multimeter and see if that matches what it is supposed to be. You can calculate what a coil’s resistance should be with the help of Ohm’s Law.

Check For Worn Bearings

Bearing failures are among the most common electric motor failures. If you find that an electric motor’s shaft cannot turn or is unusually stiff — that could have been caused either by a lack of lubrication or a failed bearing. Deteriorating bearings may also cause squeaking noises. Once again, ensure that the bearings are lubricated before deeming them faulty.

Faulty Brushes

Motor brushes (black rectangular chunks of carbon attached to springs) wear down over time, and that may cause your motor to malfunction. However, there is usually a warning such as noise, slower operation than usual, or intermittent failures. Look at the brushes to see if they firmly contact the commutator (the cylindrical copper device that spins between the brushes). If they don’t, that may be your problem. Brushes in larger motors are replaceable and usually inexpensive.

Faulty Electronic Commutator Module (ECM)

Brushless electric motors usually utilize some form of electronic commutator (with the exception of permanent-split capacitor-start, shaded pole, and some other AC current-powered motors). The electric commutator is a circuit board that may or may not be located inside the motor itself (although it is usually inside the motor).

One common example of motors without the ECM built in, but attached to the underside or near the motor is hard drive spindle motors. Diagnosis of faulty electronic commutators is unfortunately not a terribly straightforward process. One thing you can do is to check the voltage coming from the ECM (the terminals where the ECM supplies power to the motor itself).